2017 New Technology sublimation offset ink with MSDS

- Color: cyan, magenta,yellow,black

- Shelf Life: 3 years

- Packing:: 1kg/tin,2kg/tin

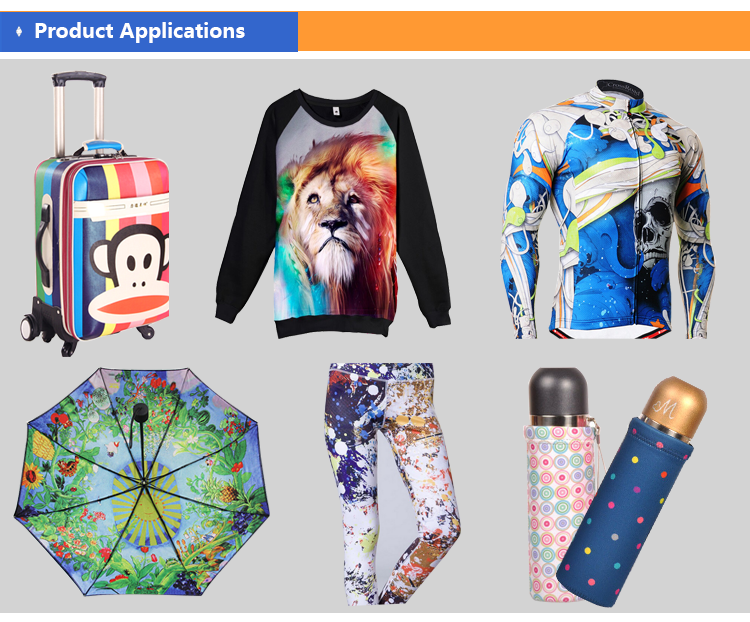

- Sublimation Offset Ink Product Description I ntroduction Sublimation Offset Ink belongs to heat transfer printing ink. There are two steps of sublimation printing. The images is printed on paper first. Then the images will transfer to fabr

Easy ways to get the answers you need.