Product Description

Dye sublimation for sportswear designed to apply a mirror image onto paper for transfer to the final substrate. The prints are transferred via heat and pressure onto most polyester or synthetic materials. When first printed onto paper, sublimation inks appear to be weaker and duller than standard inks, however when transferred onto suitable substrates, the dyes develop their true color strength and brilliance.

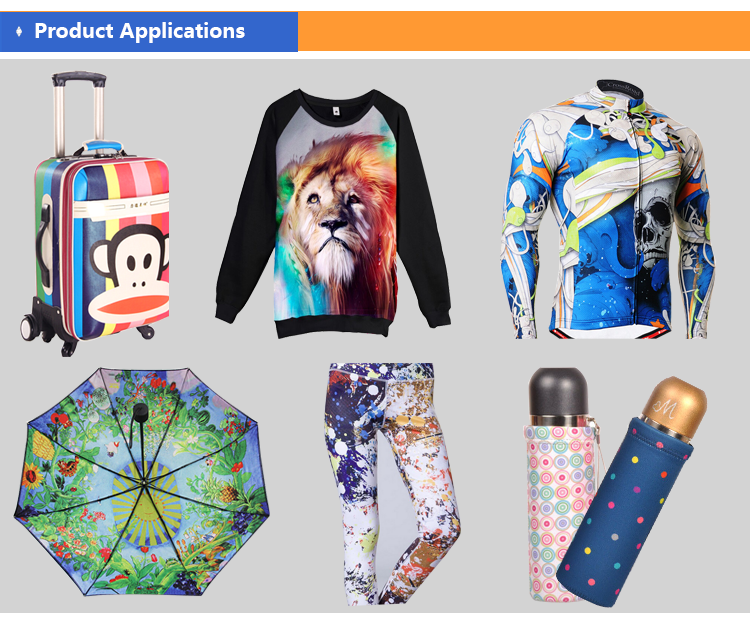

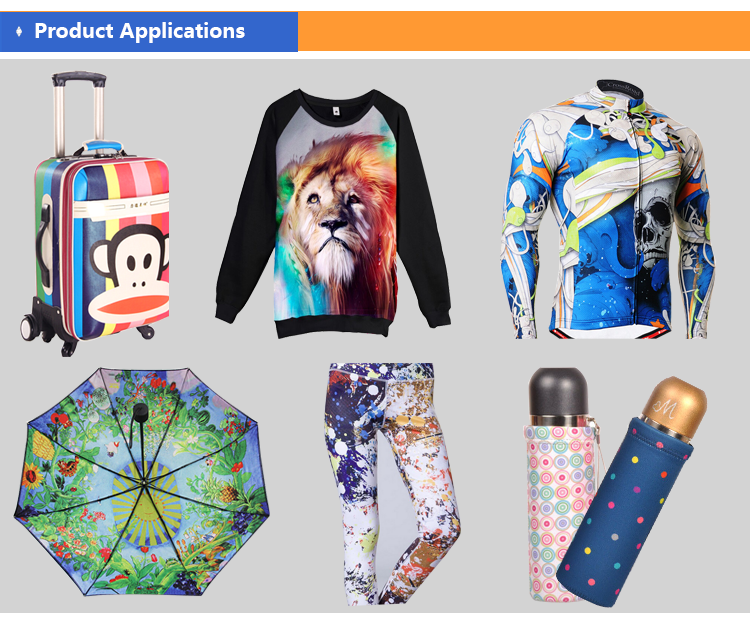

Products application

Available printer

Such as Epson, Mimaki, Mutoh, Roland, and etc.

Printed materials

Fabric, mug, plate, metal, wood, ceramic, and etc.

Use method

Use Method

First, design image on computer. Second, print the image out with the ink on paper. Third, transfer the image from paper to T-shirt or mugs or other materials by heat transfer press.

Application notice

Transfer Paper

Inkjet printing paper, transfer paper.

Transfer temparature

About 180~220°C

Transfer time

About 15~40 seconds

Transfer pressure

0.5kg/cm2

Since heat transfer printing ink for normal paper belongs to gas shading, then the colour showing on paper and the colour showing on fabric are different. So when we make PS-plate, the CMYK ratio is different from normal offset plate making.