Factory Direct Supply Sublimation Ink for Fabric Transfer

Product Description

Introduction

Heat Transfer T Shirt Printing Ink belongs to heat transfer printing ink. There are two steps of sublimation printing. The images is printed on paper first. Then the images will transfer to fabric or other materials by heat press machine. During the process of heat transfer, the ink permeate the fabric and integrate with fabric. The sublimation ink is mainly used in sportswear, non-woven bags, clothing, crafts and so on.

Advantages

1) Rich and colorful design

2) Small chromatism

3) Good reproducibility

4) Sun-proof

5) Wear-resisting

Usage method

1) Designing ideal image

2) Printing the image on paper by sublimation ink. Both digital printer or offset printer can be used.

3) Putting the paper and fabric on the heat-transfer machine. When the temperature reaches 180-220°C, the image will be transfer printed from paper onto the substrate.

4) Peeling off the transfer paper.

FAQ

1. What's the reference printing parameter?

A:

|

Fabric Name

|

Transfer Temperature

|

Transfer Pressure

|

Transfer Time

|

|

Polyester Fabric

|

205°C~220°C

|

0.5kg/cm2

|

10~30s

|

|

Polyester low flexibility Fabric

|

195°C~205°C

|

0.5kg/cm2

|

30s

|

|

Three-acetate fiber fabric

|

190°C~200°C

|

0.5kg/cm2

|

30~40s

|

|

Nylon Fabric

|

195°C~205°C

|

0.5kg/cm2

|

30~40s

|

|

Acrylic Fabric

|

200°C~210°C

|

0.5kg/cm2

|

30s

|

|

Two-acetate Fabric

|

185°C

|

0.5kg/cm2

|

15~20s

|

|

Gather propionitrile Fabric

|

190°C~220°C

|

0.5kg/cm2

|

10~15s

|

2. Which kind of paper can be used?

A: Inkjet printing paper, transfer paper.

3. What's the transfer temparature?

A: About 180~220°C

4. What's the transfer time?

A: About 15~40 seconds

5. What's the transfer pressure?

A: 0.5kg/cm2

6. What's other remarks?

A: Since heat transfer printing ink for normal paper belongs to gas shading, then the colour showing on paper and the colour showing on fabric are different. So when we make PS-plate, the CMYK ratio is different from normal offset plate making.

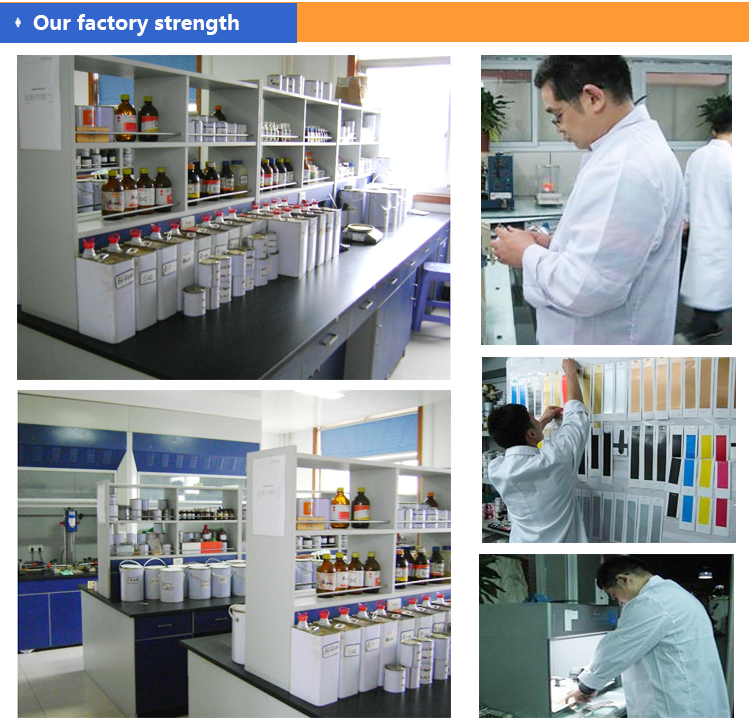

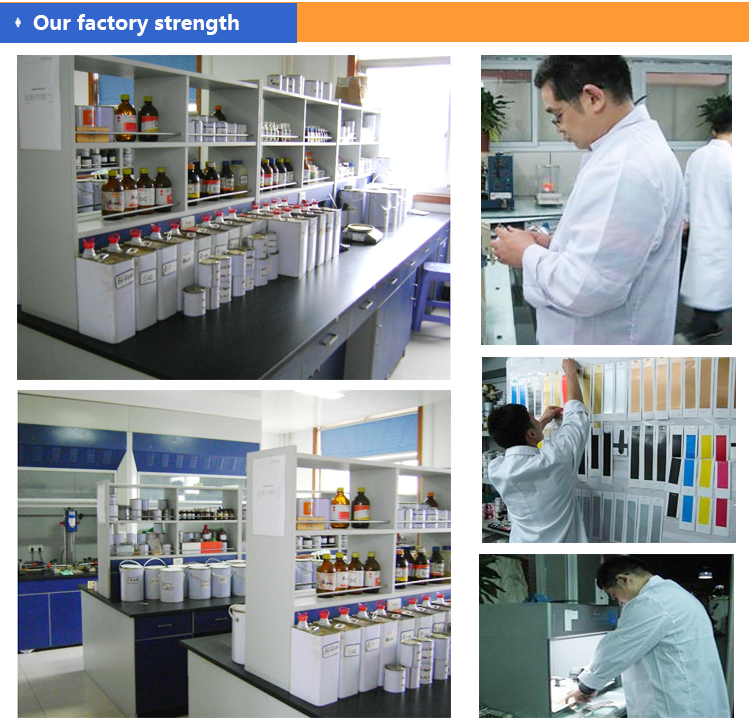

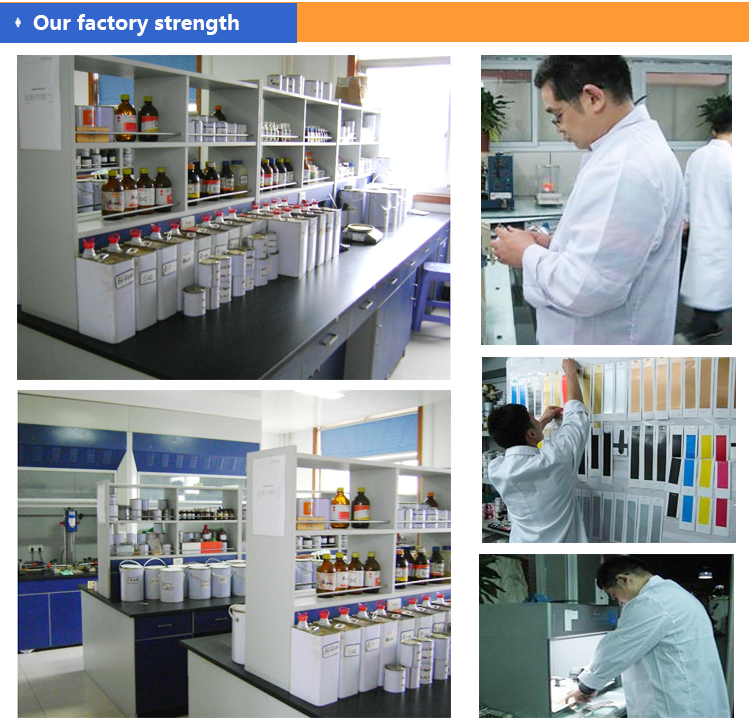

Company Information

Henan Zhongliqi Printing Material Ink Co., Ltd is the largest chinese manufacturer of heat transfer t shirt printing ink manufactures for all commercial printing applications, including offset lithography printing, digital printing, silk-screen printing and rotogravure printing.

we could supply you the best quality sublimation ink , and give you a competitive price, our products are manufactured in accordance with international standards, such as MSDS, SGS,GDM standards.

Packaging & Shipping

Packaging

1kg/tin,12kg/carton.carton inside,wooden outside.

Shipping

by ship or airplan

Heat Transfer T Shirt Printing Ink

Product Description

Introduction

Heat Transfer T Shirt Printing Ink belongs to heat transfer printing ink. There are two steps of sublimation printing. The images is printed on paper first. Then the images will transfer to fabric or other materials by heat press machine. During the process of heat transfer, the ink permeate the fabric and integrate with fabric. The sublimation ink is mainly used in sportswear, non-woven bags, clothing, crafts and so on.

Advantages

1) Rich and colorful design

2) Small chromatism

3) Good reproducibility

4) Sun-proof

5) Wear-resisting

Usage method

1) Designing ideal image

2) Printing the image on paper by sublimation ink. Both digital printer or offset printer can be used.

3) Putting the paper and fabric on the heat-transfer machine. When the temperature reaches 180-220°C, the image will be transfer printed from paper onto the substrate.

4) Peeling off the transfer paper.

FAQ

1. What's the reference printing parameter?

A:

|

Fabric Name

|

Transfer Temperature

|

Transfer Pressure

|

Transfer Time

|

|

Polyester Fabric

|

205°C~220°C

|

0.5kg/cm2

|

10~30s

|

|

Polyester low flexibility Fabric

|

195°C~205°C

|

0.5kg/cm2

|

30s

|

|

Three-acetate fiber fabric

|

190°C~200°C

|

0.5kg/cm2

|

30~40s

|

|

Nylon Fabric

|

195°C~205°C

|

0.5kg/cm2

|

30~40s

|

|

Acrylic Fabric

|

200°C~210°C

|

0.5kg/cm2

|

30s

|

|

Two-acetate Fabric

|

185°C

|

0.5kg/cm2

|

15~20s

|

|

Gather propionitrile Fabric

|

190°C~220°C

|

0.5kg/cm2

|

10~15s

|

2. Which kind of paper can be used?

A: Inkjet printing paper, transfer paper.

3. What's the transfer temparature?

A: About 180~220°C

4. What's the transfer time?

A: About 15~40 seconds

5. What's the transfer pressure?

A: 0.5kg/cm2

6. What's other remarks?

A: Since heat transfer printing ink for normal paper belongs to gas shading, then the colour showing on paper and the colour showing on fabric are different. So when we make PS-plate, the CMYK ratio is different from normal offset plate making.

Company Information

Henan Zhongliqi Printing Material Ink Co., Ltd is the largest chinese manufacturer of heat transfer t shirt printing ink manufactures for all commercial printing applications, including offset lithography printing, digital printing, silk-screen printing and rotogravure printing.

we could supply you the best quality sublimation ink , and give you a competitive price, our products are manufactured in accordance with international standards, such as MSDS, SGS,GDM standards.

Packaging & Shipping

Packaging

1kg/tin,12kg/carton.carton inside,wooden outside.

Shipping

by ship or airplan